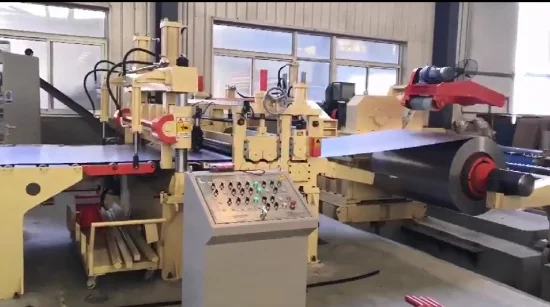

Stainless Steel Plate ESL Series Slitting Line Machine for Thick Material

Basic Info.

| Model NO. | ESL-12X1600 |

| Customized | Customized |

| Advantage | Use Widely |

| Condition | New |

| Processing Thickness | 0.3-3mm |

| Processing Width | 3X2000mm |

| Processing Material | Cold/Hot Rolled, Galvanized... |

| Packaging Material | PVC |

| Uncoiling Weight | 10t |

| Guarantee Period | 12 Months |

| Slitting Speed | 70m/Min |

| Slitting Strip Number | 6-30 |

| Applicable Process | Process Materials |

| Packaging | Film |

| Suitable Substrates | Coil, Plate, Sheet |

| Classification | Metal |

| Work Method | Flat Knife Slitting |

| Structure | Cutting Part |

| Application | Mechinery&Hardware |

| Transport Package | Seaworthy |

| Specification | CE, ISO9001 |

| Trademark | Eagle |

| Origin | Jinan, Shangdong |

| HS Code | 8462311000 |

| Production Capacity | 60 Sets/Year |

Product Description

COMPANY PROFILE :

Jinan Eagle CNC Machine Co., Ltd located in Jinan Economic Development Zone, Shandong Prov., China, is a professional manufacturer of metal coils and sheets processing machinery.The main products include Cut-to-Length lines, Slitting lines, Tension Leveling lines and Precision Leveling machines, etc. Four series with multi-varieties and multi-specifications.It is one of the few specialized, large-scale, middle and high-end suppliers of coil processing equipment in China.

Product Details:

Slitting line ESL -1x1300:

It is composed of the following:

1. entry coil car,

2. uncoiler,

3. slitter,

4. scrap coiler,

5. tension unit,

6. recoiler, etc.

Our slitting machine carries out slitting on cold or hot rolling carbon steel, tinplates, stainless steel, and other kinds of metal that have coated surfaces. It is a useful slitting machine, widely used during the processing of home appliances, automobiles, hardware, steel products and moreAdvantages:1. High cutting quality2. High utilization rate of materials3. Stepless cutting speed regulationUncoiling Unit

1. Several coils can be pre-placed on the loading station to improve working efficiency.2. This uncoiling unit of our slitting line adopts a hydraulic collapsible drum, which does no harm to the sublayer of the material. It is capable of carrying out tensile uncoiling or manual material unloading, which effectively prevents the material from deflecting and scraping. 3. Both single-head and double-head type uncoiling units are available.

Slitting Unit

1. The slitting head arbors are fixed in eccentric sleeves. The slitting angle remains unchanged if the blade has just been polished.2. This slitting line has two slitter heads. While one is running on line, kives setting up can be done on the other, which can greatly eliminate production down-time. As a result, this slitting line carries out slitting and blade changing simultaneously. This greatly increases the working efficiency.3. Hydraulic locknuts could be used for higher blade positioning precision.

Tension Unit

1. Two pre-separation devices are fitted to this tension unit. The disengaging shaft could be transversely removed for faster switching of separating plates.2. It has a friction type tensile working table. The adjustable tensile could be offered by hydraulic power or pneumatic power.3. Our slitting line could also be equipped with a roller type tightening machine, which is suitable for materials of coated surfaces because it does not harm the coated surfaces.

Coiler

1. Our slitting line could be fitted with a seamless hydraulic expansion coiler, which does not damage the sub-layer of the material.2. The material clamping device has stress reducing characteristics. The roundness of the winding drum remains unchanged for plates of different thickness.3. It carries out firm, dense and neat coiling.

Parameters of Slitting Line

Model/ Items | Thickness (mm) | Width (mm) | Slitting Number | Slitting Speed m/min | Coil Weight (ton) |

ESL-0.5x1000 | 0.15-0.5 | 300-1000 | 12 | 50-150 | 7 |

ESL-0.5x1300 | 0.15-0.5 | 500-1300 | 24 | 50-150 | 7 |

ESL-2X650 | 0.3-2 | 200-650 | 10-30 | 50-150 | 7 |

ESL-2X1000 | 0.3-2 | 300-1000 | 10-30 | 50-150 | 7/15 |

ESL-2x1300 | 0.3-2 | 500-1300 | 12-30 | 50-180 | 7/15 |

ESL-2x1600 | 0.3-2 | 500-1600 | 12-30 | 50-180 | 7/15 |

ESL-3x1600 | 0.3-3 | 500-1600 | 8-30 | 50-180 | 15 |

ESL-3x1800 | 0.3-3 | 900-1800 | 8-30 | 50-180 | 20 |

ESL-4x1600 | 1-4 | 900-1600 | 6-30 | 50-120 | 20 |

ESL-6x1600 | 1-6 | 900-1600 | 6-30 | 30-80 | 30 |

ESL-10x2000 | 2-10 | 900-2000 | 5-30 | 30-50 | 30 |

ESL-12x2000 | 3-12 | 900-2000 | 5-30 | 20-40 | 30 |

ESL-16x2000 | 3-16 | 900-2000 | 5-30 | 20-40 | 40 |

Transaction procedure:Inquiry - Project - Sign - Production - Inspection - Payment - Transportation - Installation& Commissioning - GuarantyJinan Eagle CNC Machine Co., Ltd (briefly JEM), located in Jinan city, Shandong Province, China, was founded in 2003. It is mainly engaged in developing and manufacturing of Cut to Length Line, Slitting Line, Rotary Shear, Slitting and Cut to Length Combined Line, Leveling Machine, Tension Leveler and so on. Our products are widely used in transfomer, motor, household appliance, automobiles, hardware, steel industries, etc. It can be used for processing cold and hot rolled steell, carbon steel, galvanized steel, silicon steel, tinplate, stainless steel, pre-painted steel, aluminium, copper and other metals.Domestic customers include First Automotive Works (FAW), Second Automotive Works, Great Wall Automobile, Bao Steel, Anshan Steel, Handan Steel, Midea Group etc, and many of coil processing centers. Internationally, our products have also been installed in Europe, South America, Africa, Southeast Asia and so on.

Welcome you to our factory!